Featured image from Unsplash

Laser devices can perform an extensive number of tasks, including surgeries. For example, you can get corrective eye surgery that uses lasers to reshape the cornea. Architects and surveyors also use lasers in their work.

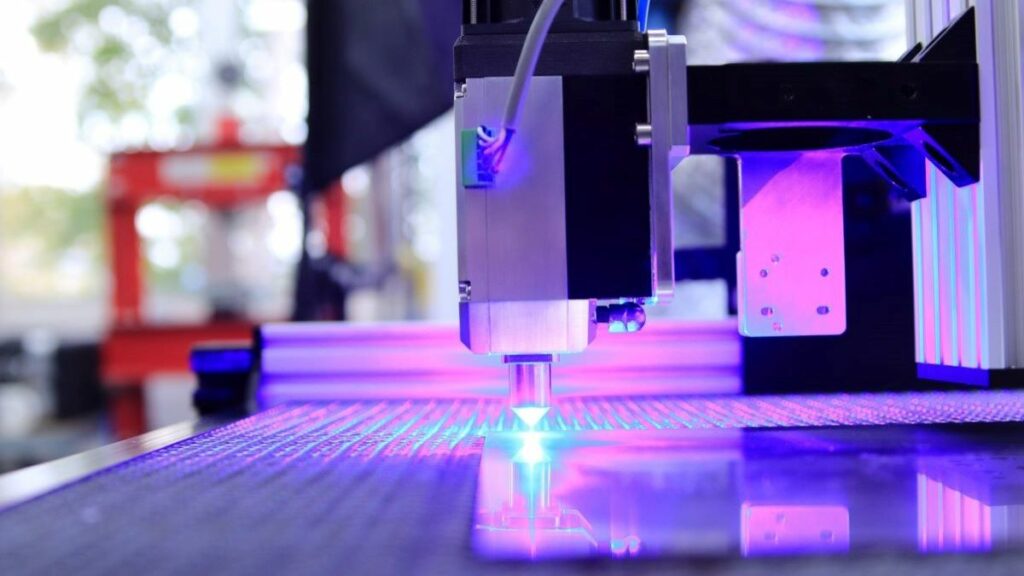

Another type of laser in use in business and industry today is the fiber laser for engraving purposes. This article focuses on desktop fiber laser engraving machines, beginning with a brief history of lasers. Then we discuss how lasers work and provide information on their uses across various industries. We also explore the key benefits of this type of equipment.

The History of Lasers

Lasers have been present in commercial and industrial settings since the 1960s. The idea of using lasers for a range of applications was first proposed by Albert Einstein more than a century ago when he wrote a paper describing the potential for such technology. It took several decades of further research and development before the first lasers would be produced.

How They Work

Fiber lasers are known as solid-state lasers. This is because they use a medium that is a solid material rather than a liquid, such as the liquids used in dye lasers, or a gas, as is used in gas lasers. Instead, fiber lasers rely on an optical fiber that is then “doped,” or mixed with a rare earth element. This allows for the creation of a laser beam with a specific wavelength. Depending on the rare earth element the particular equipment uses, wavelengths can vary considerably, making the fiber laser suitable for a wide range of tasks.

Fiber lasers work in five specific stages:

- First, electricity powers the laser. Then diodes convert the electrical energy into light energy.

- A coupler combines the light energy from the diodes, then it flows through the optical fiber to the laser medium.

- Next, the light energy reaches the laser cavity, which is the doped part of the laser unit.

- Once the laser comes into contact with the doped rare earth elements, it goes into a state of population inversion, which amplifies the light. This process is essential for the creation of a standard laser.

- The final stage is the further amplification of the laser light into a concentrated beam. This is achieved by means of fiber Bragg gratings, a system of mirrors that reflect and focus the laser beam.

RELATED ARTICLE: 6 WAYS 3D PRINTING SAVES BUSINESSES MONEY

Common Uses of Fiber Laser Engraving Machines

A wide range of industries rely on fiber laser engraving machines for a multitude of purposes. Some of these include:

- Industrial environments

- The jewelry industry

- Workshops

- Crafting firms

- Car component manufacturers

- Signage companies

- The aerospace industry

- Manufacturing

Portability of Modern Fiber Laser Equipment

Modern fiber laser equipment has several benefits. Portability of the units is a key one. Early designs tended to be large and bulky, which often meant that they could only be used in one location in a factory or workshop. It would take a considerable amount of time and effort to move one of these early machines to other parts of the premises.

Today it is possible to purchase a desktop fiber laser engraving machine, or desktop laser engraver, that is truly portable, thanks to its smaller area. This makes such equipment ideal for use in smaller workshops such as jewelers or compact industrial units. It also means that workers can easily move the equipment to different locations in the premises for a range of specific tasks having to do with the production line of a manufacturing firm.

Accuracy and Consistency

Another key benefit of these systems is that they can work to extremely high levels of accuracy and consistency. Depending on the chosen size of the beam, they can engrave on exceptionally small areas while producing script or coding that is still legible to the human eye. This is perfect for engraving on extremely small components or when jewelry or similar items require intricate engraving. The consistency of this equipment is such that it guarantees uniformity of results every time.

RELATED ARTICLE: TECHNOLOGY OR MONEY: WHICH ONE MAKES THE WORLD GO ROUND?

No Need for Chemicals

In the modern world, there is a need for all businesses to be able to demonstrate that they operate in an environmentally responsible fashion. Companies must take steps to ensure that they eliminate waste from their production or manufacturing processes and minimize the effects that they have on the wider environment.

When your company uses a fiber laser unit for engraving tasks, however, you will have no need for any chemicals for this part of your process. The laser beam will engrave by accurately burning the host material, producing no waste or hazardous products. This may also offer your business a cost saving when compared to engraving methods that rely on the use of other solutions or chemicals to operate.

RELATED ARTICLE: COSMETIC LASERS: LATEST TRENDS IN THE TREATMENT MARKET