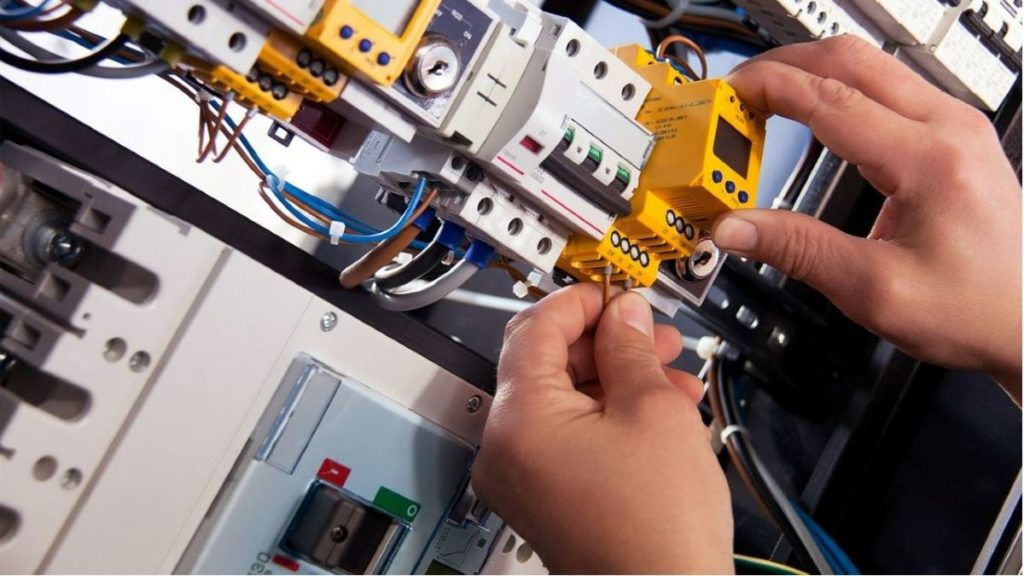

Featured image by Harry Strauss via Pixabay

All electrical equipment deteriorates over time, no matter how little or often anyone uses it or what its function is. Of course, these factors will have an effect on the extent of deterioration.

Legally, however, there is little guidance on how you should maintain electrical equipment or how you should test it. Nonetheless, it is especially important to maintain equipment in the workplace, whether it belongs to the employer or the staff brings it in.

What Should I Consider When It Comes to Maintaining Electrical Equipment?

When deciding on what level of maintenance your electrical equipment requires, you should consider whether the equipment is earthed or double insulated.

It’s also worth thinking about the increased risk if you or your employees use the equipment in a particularly challenging environment. Also think about whether or not the equipment is suitable for the job at hand. Using equipment incorrectly will increase its risk of deterioration.

What Steps Should I Take to Maintain Electrical Equipment?

If you are an employer, there are plenty of things you can do to ensure that electrical equipment meets required standards of safety. For example, you should instruct employees to check supply cables and the equipment itself before they use it. Also, sign up any equipment that is not double insulated for a Portable Appliance Test at intervals of between one and five years.

Additionally, if any electrical equipment is in poor condition, remove it from use without delay. Otherwise, you’re running a greater risk of an accident occurring. Only persons who have the relevant skills and training should repair faulty equipment. Those who aren’t qualified can harm themselves and others by attempting to repair electrical appliances.

How Important Are Visual Checks?

Visual checks are essential to maintaining safe electrical equipment. In fact, a visual check can often identify potential problems before a dangerous problem arises.

Visual checks help to identify whether equipment is suitable for the job. A simple visual inspection can tell whether circumstances have changed. A quick check of the maintenance records can tell you whether the user has reported any issues.

For example, teach employees to look out for loose plugs, fraying wires, cracked or loose casings, and loose terminal screws. If you discover during a visual inspection that your workplace needs any replacement parts, reach out to standardelectric.com for the equipment you need.

Review inspection and testing intervals regularly to make sure qualified personnel are carrying them out often enough. It’s helpful to keep a log of this. If you have an electrically competent person on site, they should be using the correct PAT testing equipment to ensure the electrical safety of other employees. You can purchase this equipment from specialist retailers such as PASS.