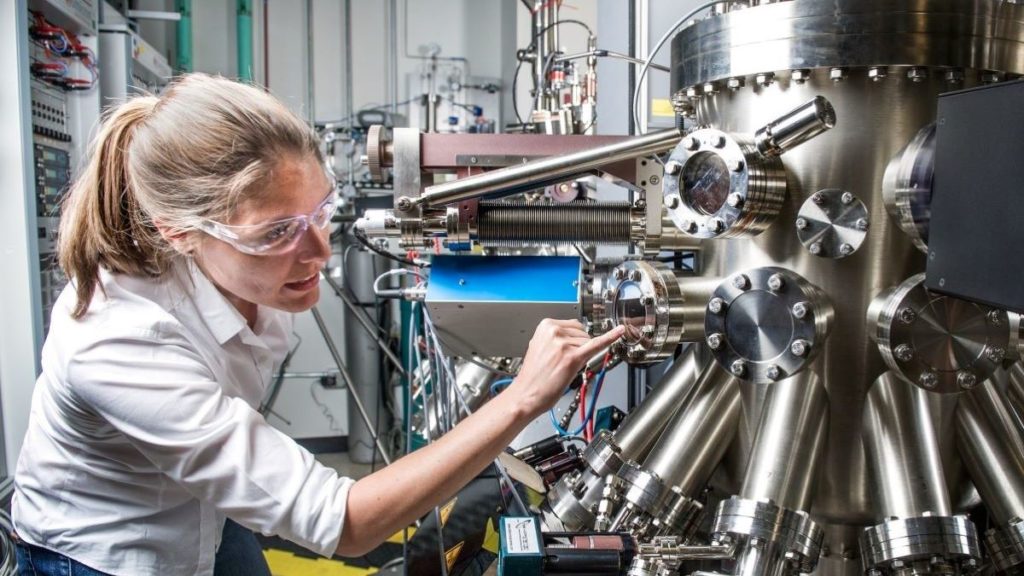

Featured photo by Science in HD on Unsplash

Most manufacturing companies operate on razor-thin margins. Just about any product available has a lot of competition. This makes it hard to make a lot of profit as a manufacturing business, because you have to price according to your competition.

To make more money, raising prices is not usually the way a manufacturing business should go about it. Instead, it makes more sense to try to cut costs and increase the profit margins that way. However, this is easier said than done.

A lot of these things are not going to look like anything significant when it comes to savings, but they will add up over time. If you want your plant to be competitive then the sooner you can save money the sooner you’ll make more.

In this article, we highlight a few of the ways your factory can save money.

1. Equip Your Manufacturing Business with a Smart Security System

You probably already have an alarm system for your factory. But having a smart system can do so much more and save you money in the long run. A smart alarm system allows the company to use WiFi rather than a complex closed circuit system. This can save you a lot of money.

Monitoring is much less time-intensive from a human perspective. What’s more, you’ll have digital video, and that will provide even more savings.

An example of where a smart security system would help is that you can install cameras that begin to operate when there is movement. These can be especially useful in sensitive areas. Additionally, you can monitor your system remotely around the clock more reliably and for a lower cost than you could pay human beings to perform the same function manually.

2. Perform Predictive Maintenance Regularly

Maintaining equipment in your manufacturing business is a great way to save money. It will cost far less to maintain your equipment than replace it. However, even regularly scheduled routine maintenance is not necessarily the best way to save money.

Predictive maintenance technology is a smarter way to go. It uses AI to predict when your machinery needs to be serviced so that you aren’t wasting money and resources servicing a machine that isn’t ready for it.

RELATED ARTICLE: THE IMPORTANCE OF PREDICTIVE MAINTENANCE IN MANUFACTURING

Data and analytics are used to understand when a part actually needs to be replaced and when it doesn’t. This way you are only spending money on parts that are at the end of their life, even if it is before or after when it would normally be expected.

3. Change the Lights in Your Factory

One of the biggest ways to save money in a factory is by changing the lights. If the lights in your manufacturing business are incandescent or even fluorescent, you are spending money needlessly. Going with LED instead will save you money.

For one thing, the bulbs will last far longer than traditional ones. For another, the cost savings in energy is one of the soundest ways to cut costs.

What’s more, your costs for cooling the factory will be lower when you have LED lights rather than incandescent, because LED bulbs don’t ever get hot. Click here to find further ways to save manufacturing cost through smart recycling.

4. Always Negotiate

Everything is negotiable for a manufacturing business. This goes for everything from how much vendors pay you for your scrap to how much you pay for your materials. Always be on the lookout for an opportunity to negotiate.

Moreover, if you always have an eye on what is happening globally, you may spot an opportunity to use a storm, a faltering economy, or new tariffs imposed on a competitor to ask for a change in your terms. This can lead to some dramatic savings when things change again.