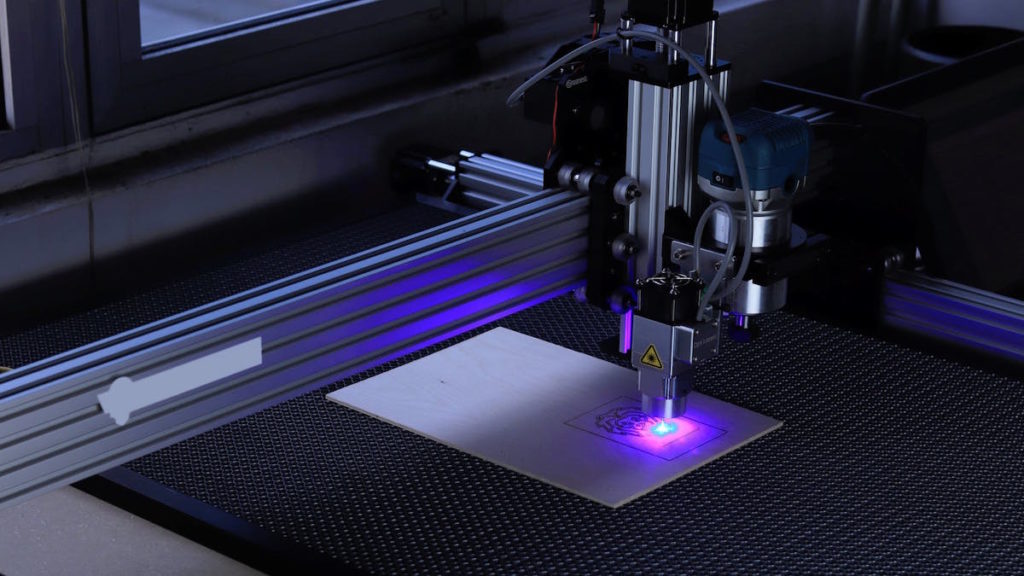

Featured image by Opt Lasers on Pexels

When you’re managing a business that requires specific composite materials to be manufactured for your products, you need to be sure you will get precise results. Whether you need an everyday product that requires exact alterations or you need something more innovative. You want to be sure you’re dealing with a professional business capable of delivering quality.

The Benefits of Full Service

One of the best ways to know that you’re working with a professional business, that can deliver the specifications you require, is to look for a company that offers a wide range of services. This is important because you do not want to rely upon a manufacturer who may have to out-source multiple services or tasks.

Also, it is important to work with a professional company with a good amount of experience. If you’re looking for a manufacturer of carbon fiber for a new product you aim to sell, one of the best ways to find a reliable company is to ask about the services they offer for carbon fiber and other composite materials. Do this before you agree to work with them to avoid a headache in the future.

RELATED ARTICLE: PRODUCT SHIPPING: FREIGHT FORWARDERS AND BROKERS

A Wide Range of Quality Products

The manufacturing of composite materials has changed significantly in the past hundred years. However, one thing that hasn’t changed is the motivation for quality. The driving force behind all of that development is the ambition to create a superior product by combining two available ones.

The combination of diverse materials involved in creating a new composite material can be achieved using a variety of methods, including:

- Open Molding

- Resin Infusion

- Hand Lay-up

- Pre-Preg

- Autoclave Curing

- Urethane Casting

Before picking a manufacturing company to work with, make sure they offer a wide variety of unique services to satisfy your business’s needs.

RELATED ARTICLE: TOP 3 QUESTIONS ABOUT MERCHANT PROCESSING SERVICES

Servicing Various Industries

Composite materials are in high demand across a wide variety of industries. This is because they provide a cost-effective option, tend to be lighter than regular metals, and are highly durable.

Some of the industries that continuously require composite manufacturing include:

- Medicine

- Marine Craft Manufacturing

- Automotive

- Aerospace

- Construction

- Industrial Equipment

- Defense

So, if you’re an owner of a new manufacturing business, the chances are that you’re probably already aware of the need for high-quality materials in your products.

3D Printing Capabilities

3D printing is a fairly new concept. However, it has rapidly proven to be an essential part of the composite manufacturing process, especially for industries that require innovation. When a company can provide you with a 3D printed prototype, the process will move very quickly and save you money. For some materials, the entire process can be completed using a 3D printer.

Final Thoughts

The products that you sell are only as good as the quality of the components that go into them. That’s why you need to be sure you’re working with a composites manufacturer that can deliver top-quality parts. Now that you know the kinds of services offered in composite manufacturing, the best way to get starts is to contact a company and discuss what they can offer your business.

RELATED ARTICLE: HOW YOU CAN START A MANUFACTURING BUSINESS