If your company relies on shrink wrap packaging you should consider investing in shrink wrap machinery to help optimize your operations.

RELATED ARTICLE: USING AND MAINTAINING INDUSTRIAL MACHINERY

When it was first introduced, shrink wrap revolutionized the packaging industry. Because it is versatile, durable, and eco-friendly, shrink wrap packaging solutions are suitable for use in numerous industries and business sectors, including manufacturing, distribution, banks, and government institutions.

Shrink wrap films come in a wide range of strengths, transparency, and thicknesses, making it ideal for both small- and large-scale operations. It can even wrap entire structures.

Many industries choose polyolefin (POF) packaging solutions because of its benefits for businesses. In fact, POF is the principal packaging solution for numerous consumer goods, including electronics, books, and CDs.

POF is also widely used to package beverages and foodstuffs like meats, vegetables, and cheeses. The film is waterproof, weatherproof, and tamperproof. Therefore, it protects products from decomposition, water damage, and contamination while in storage and during transit.

Additionally, it makes products more appealing as consumers can see through its ultra-high-clarity aesthetics. It also allows branding and image printing for optimized visual effect on end-users.

How Has Shrink Wrap Machinery Changed?

Companies who rely on shrink wrap packaging should consider investing in shrink wrap machines to help optimize their operations. Using efficient packaging machinery means businesses can ensure they are properly applying shrink wrap films to products. This enables an increased throughput rate.

The machinery can also help firms minimize packaging waste and labor requirements. Naturally, this allows them to direct more resources toward achieving core business functions.

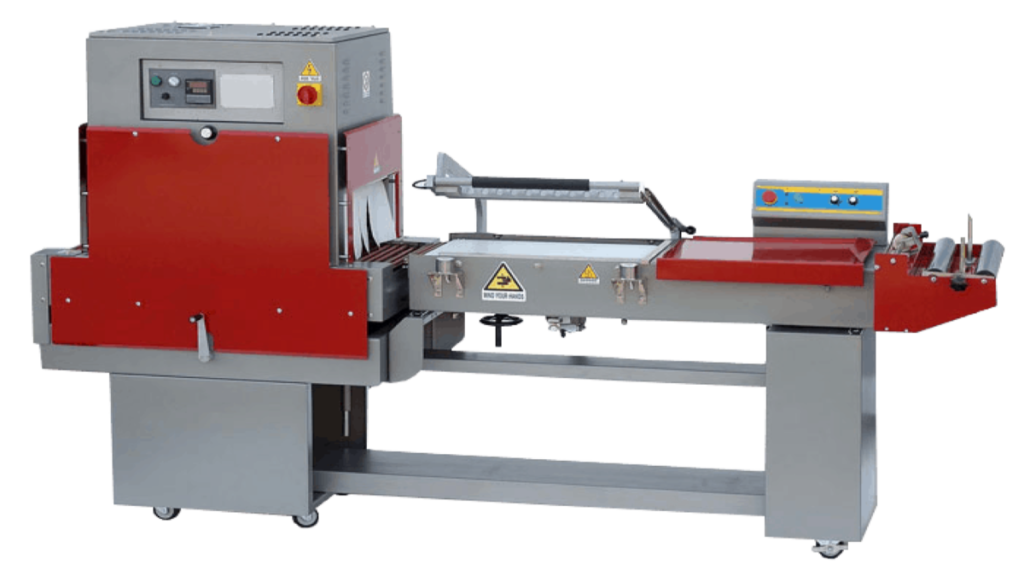

There are several types of shrinkwrap machines available in the market. However, manual models are being phased out to create room for newer, more advanced, and better automated shrinkwrap machines. Advancements in semi-automated and fully automated machines help businesses maximize resources and streamline their operations.

Compared to manual packaging systems, automated machinery has numerous benefits, especially when it comes to streamlining product packaging operations. It is a clean and safe packaging solution that provides companies with more efficient packaging solutions.

Businesses also enjoy the benefits of reduced packaging waste with automation. Moreover, they benefit from reduced labor requirements and increased output rates.

Why Should Your Businesses Invest in Automated Shrink Wrap Machinery?

Automation can be great for businesses that need to package their products. This can include anything from food to dry goods to beauty products and toys.

Moreover, rising concerns about sustainability have propelled shrink wrap companies to provide greener shrink wrap packaging options to the market. This includes efficient automated packaging machinery and shrink wrap films that contain renewable or recycled materials.

Below are some of the benefits of automation over manual packaging solutions:

Profit from Reduced Packaging Waste with Shrink Wrap Machines

Shrink wrapping is a low-cost packaging technology that enables companies to direct more of their resources toward meeting core objectives. However, manual wrapping techniques can create a lot of waste from trimming materials and incorrectly applying shrink wrap to products.

However, through automation, companies can set the packaging options to optimize the packaging process. This allows them to minimize packaging resources per product.

In short, automated packaging machines ensure that the proper amount of shrink film is applied to a product. This helps to minimize packaging waste.

Enjoy an Increased Throughput Rate

Shrink wrap machinery can substantially increase the number of items packed per minute. Therefore, automated shrink wrap machinery helps businesses streamline their entire packaging supply chain through dynamic custom packaging solutions.

Operators can easily set up machine protocols to meet product specifications. They can then allow the machines to run automatically, enabling mass packaging. This is generally a lot faster than manual packaging.

What’s more, it requires much less human labor for packaging products.

Benefit from More Efficient Packaging Solutions

Automated shrink wrap machines provide more efficient packaging solutions for enterprises. They facilitate product packaging by enabling machine operators to pass wrapped goods through a heat shrink tunnel.

This creates a sealed film around products. The heat enables POF to shrink evenly around products, making it possible to package any item regardless of its shape.

Additionally, with automation it is possible to set the system up to work at optimal temperatures and greater heat efficiency for every wrapped product.

Adapt Shrink Wrap Machinery for the Products Your Factory Produces

The machinery used for shrink wrap packaging is modular. Therefore, businesses can adapt it to fit the space and layout of their production facility.

Furthermore, because of the nature of the application process, shrink wrap machines are usually able to handle a wide range of pack sizes. This is great for companies who may need to wrap several different types of products in the same packaging facility.

It is evident that automated shrink wrap machinery promotes the optimized use of a company’s resources. This is an important part of working toward a more sustainable future.

Furthermore, many businesses are adopting bio-sourced, recyclable, or compostable and biodegradable packaging options to help promote environmental sustainability.

This is where eco-friendly shrink wrap and efficient shrink wrap machinery can offer a great deal of benefit as a packaging option. Investing in automated shrink film machinery can enable businesses to realize greater returns on their investments in their in-house packaging operations.

RELATED ARTICLE: THE IMPORTANCE OF PREDICTIVE MAINTENANCE IN MANUFACTURING

Conclusion

As the packaging industry continues to evolve, there is a need for companies to keep up with emerging trends and technologies. Automated shrink wrap machinery improves efficiency, reduces workforce labor requirements, and allows companies to optimize packaging processes and focus more resources on core business activities.

RELATED ARTICLE: 7 ESSENTIALS FOR WAREHOUSE OPERATORS